100% Original Factory Plywood Bed Board - hPX305 Hospital Bed Support Bedboard –

100% Original Factory Plywood Bed Board - hPX305 Hospital Bed Support Bedboard – Detail:

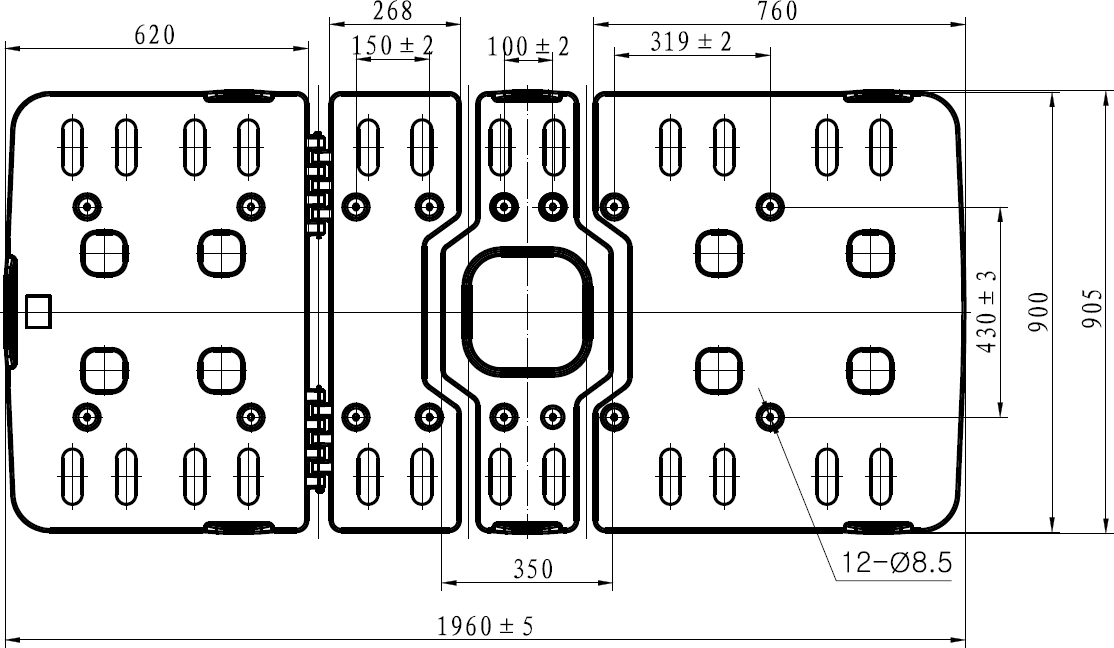

Product parameters

| Dimension | 1960*905*40mm |

| Static load | 500KG |

| Weight | ≤13KG (±0.5KG) |

| Material | High strength engineering plastics(Polyethylene).PE |

| No assembly required | Just take it out of the package and put it in place |

| Package | Cartoon |

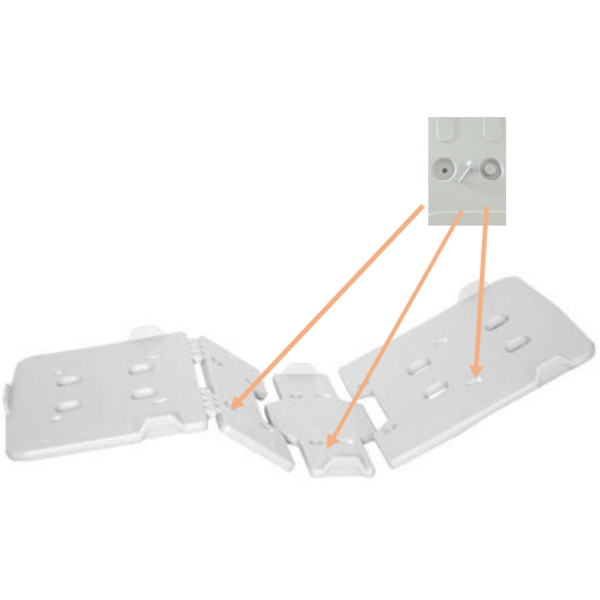

Two-ways regression.Help to reduce both sacral pressure and displacement of the patient.

4 section PP mattress-support board is waterproof, rustproof and readily accessible for cleaning and maintaining which required no tools.

What is the hospital bed board?

A stiff thin wide board inserted usually between bedframe and mattress.

What are hospital bed board used for?

Suitable for all kinds of hospital beds, nursing beds, medical beds etc.

FAQ

1.What is the philosophy of the company?

Business philosophy: customer centered, independent innovation, develop steadily and surely, resolutely shoulder responsibilities.

Customer centered: customer’s demands-oriented, promote added value of products and solve customer problems.

Independent innovation: Provide customers with competitive products and solutions to form own system for intellectual property rights.

Develop steadily and surely: Be more international and professional through sustainable development in the competition.

Resolutely shoulder responsibilities: Adhere to open cooperation philosophy, shoulder social responsibilities and address social demands, as well as build a harmonious environment together.

In terms of business model, macro business model of the company is customer-oriented and industrialization-oriented, and the development of products is guided by the demands of customers and society. The only value and reason for the company’s existence is to provide customers with complete and timely services.

2. How to Implement Quality Control in Manufacturing?

First,we create and document an approach to quality control. This includes: Defining the quality standards for each product.

Selecting the quality control method.

Defining the number of products/batch that will be tested.

Creating and training employees for quality control.

Creating a communication system for reporting defects or potential issues.

Next, to create procedures for handling defects. Consider the following: The batches will be rejected if defected items are found. There will be further testing and potential repair work involved. The production will be halted to ensure that there are no more defective products created.

Finally, use a effective method to identify the root cause of the defect, make any needed changes, and ensure all products are defect free.

Product detail pictures:

Related Product Guide:

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of 100% Original Factory Plywood Bed Board - hPX305 Hospital Bed Support Bedboard – , The product will supply to all over the world, such as: Norwegian, Nigeria, Casablanca, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.